Integrated Products of LEO TEXTILE

WHAT IS IT?

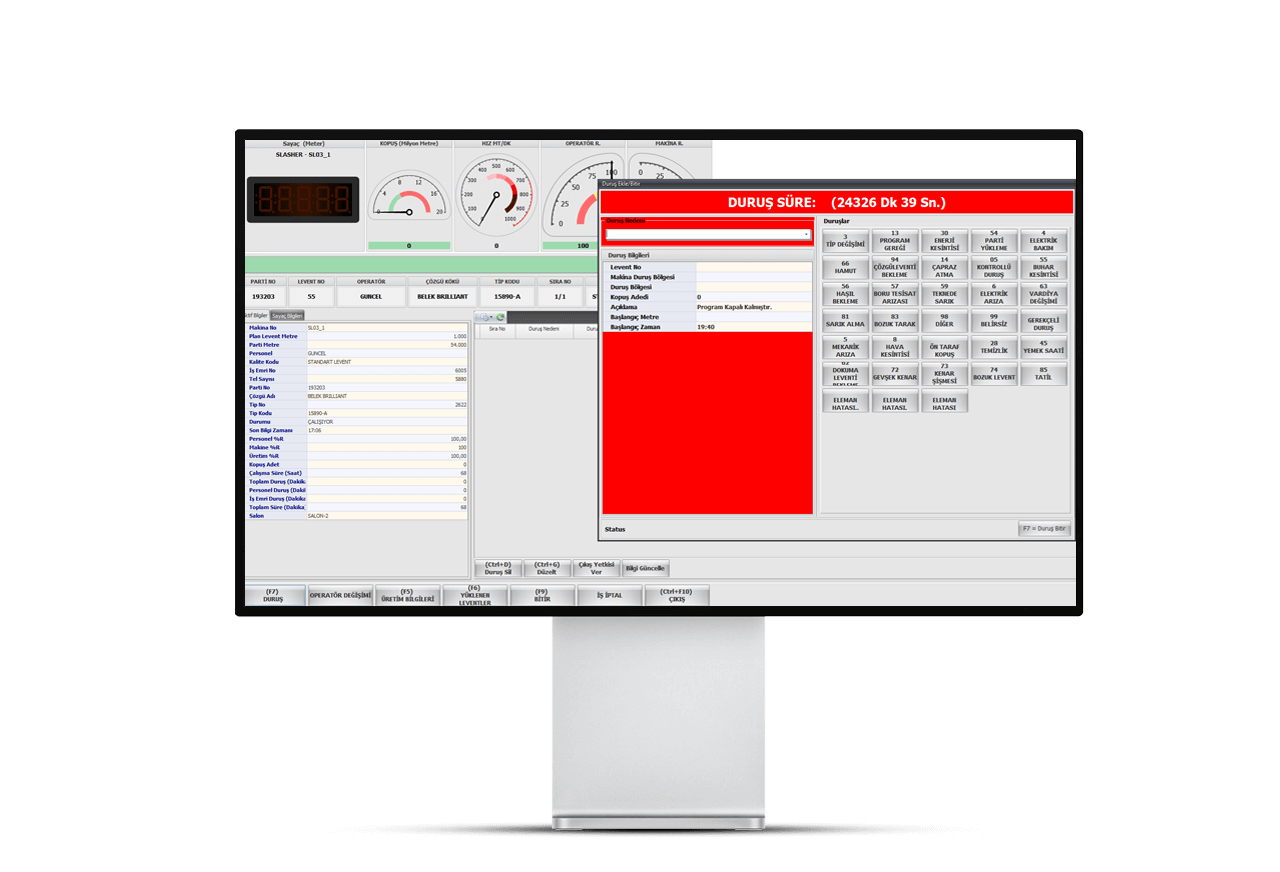

LEO PULSE, one of LEO TEXTILE’s production programs, is a software that enables real-time production monitoring by taking data from machines (WİLOOM) and displaying production values on counters within the program.

LEO PULSE can display real-time production quantity, machine speed, operator efficiency, machine efficiency, temperature, and humidity on a single screen. In addition, it shows the standard information of the ongoing batch (Job Order, Batch Number, Type Name, Quality, etc.).

Automatically transitioning to a halt during machine downtime, LEO PULSE can report the most realistic work analysis of the batch through detailed downtime entries.

The work done in LEO PULSE can also be monitored in real time through the main LEO TEXTILE program. This also allows batch tracking and instant interventions to be monitored by management.

WHAT IS IT?

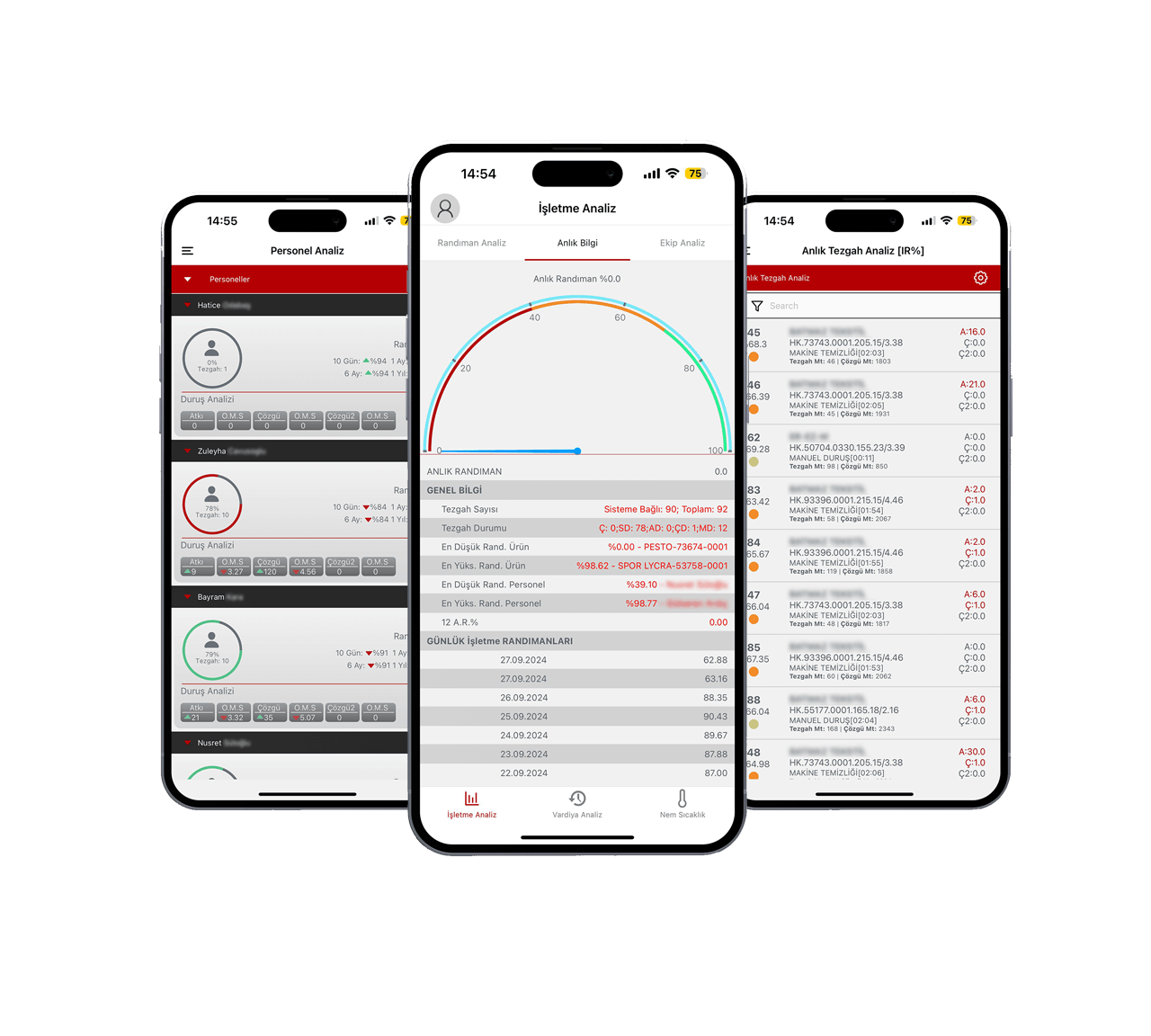

Feel the heartbeat of your business in your pocket with the Loom Monitor mobile application! Monitor your business from your mobile phone. Perform efficiency analyses for looms, staff, and products from anywhere, anytime.

- View Loom Status

You can perform real-time and historical analyses of efficiency, production, and downtime for all looms.

- Downtime Analysis

Track the min-max-average durations of each downtime definition in the business, along with efficiency loss analyses.

- Staff Analysis

Analyze staff’s weft and warp intervention durations, efficiencies, and other statuses within the team weekly, monthly, and yearly.

- Product Analysis

Get instant insights into the number of worked fabrics, the best-worst loom information, weft-warp break analyses, and information about problematic threads and warps.

WHAT IS IT?

By establishing a barcode system infrastructure for your hanger, sample, and presentation materials at the fair:

- You can quickly access the price list,

- Accurately record customer information and received orders,

- You can provide/submit a copy of the order information to the customer,

- You can track your operations on both a mobile application and a Windows application on two different platforms,

- You can achieve synchronized operation of your mobile and Windows applications without the need for the internet,

- You can perform barcode scanning operations using your desired barcode reader device on your Windows application or through the Mobile application,

- You can view analysis reports of sales made during the fair,

- You can instantly provide your order form to the customer as both an email and a printout,

- You can send your order information to the factory via email now and initiate the shipment process,

- After the fair, you can transfer your order-sales-meeting records to the LEO TEXTILE system with a single process without additional steps.

WHAT IS IT?

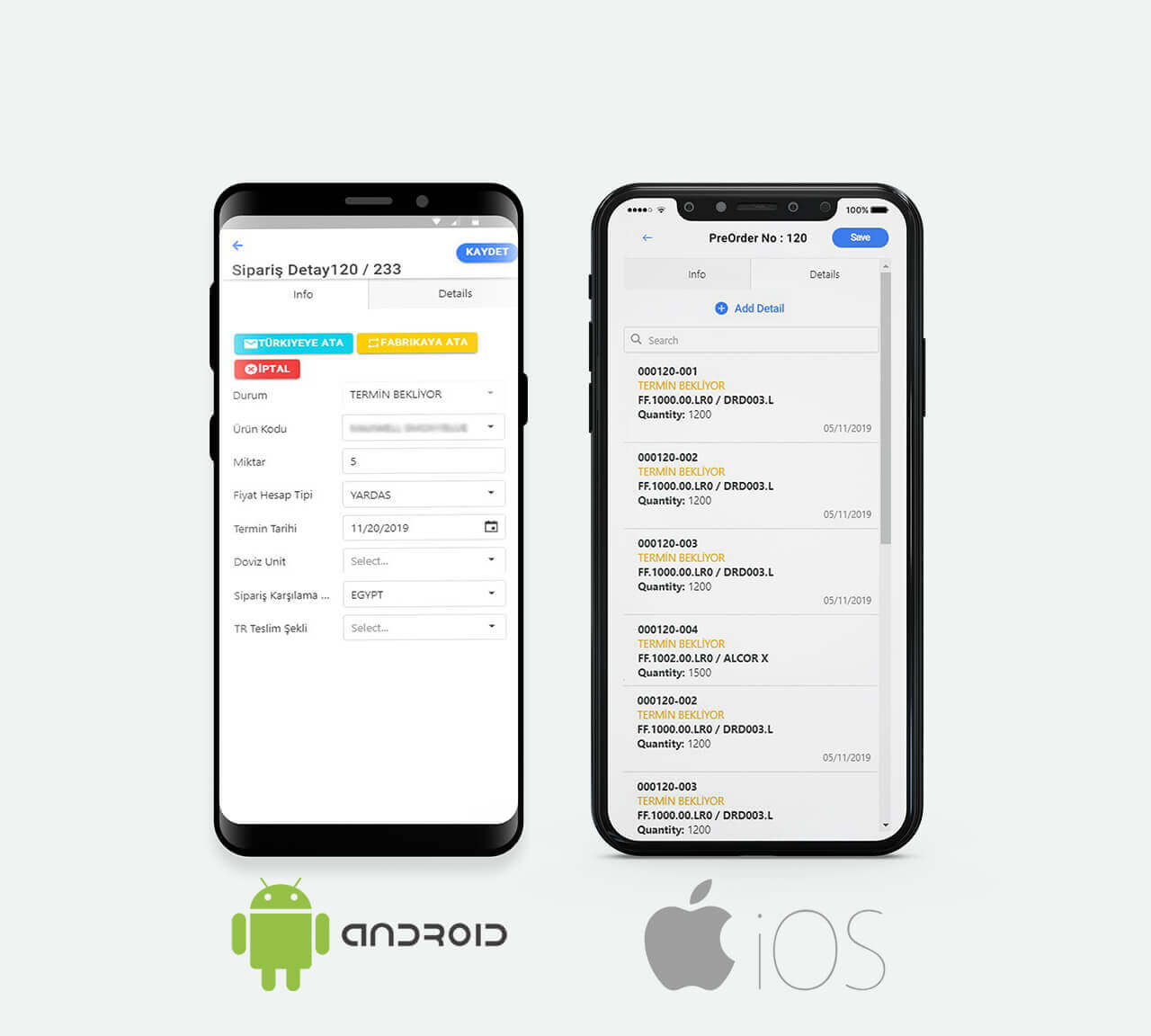

The Pre-Order Mobile application has been developed for individuals working in the marketing department to receive pre-orders (order quotations) outside the company.

With this mobile application, you can quickly perform tasks such as:

- Entry of Pre-Order header information

- Entry of Pre-Order detail information

- Listing Pre-Orders

- Viewing current stock quantity

- Listing approved orders

Benefits of the Application

Maintaining accurate and organized information in pre-order entries speeds up converting pre-orders into confirmed orders and accelerates the workflow in the planning department.

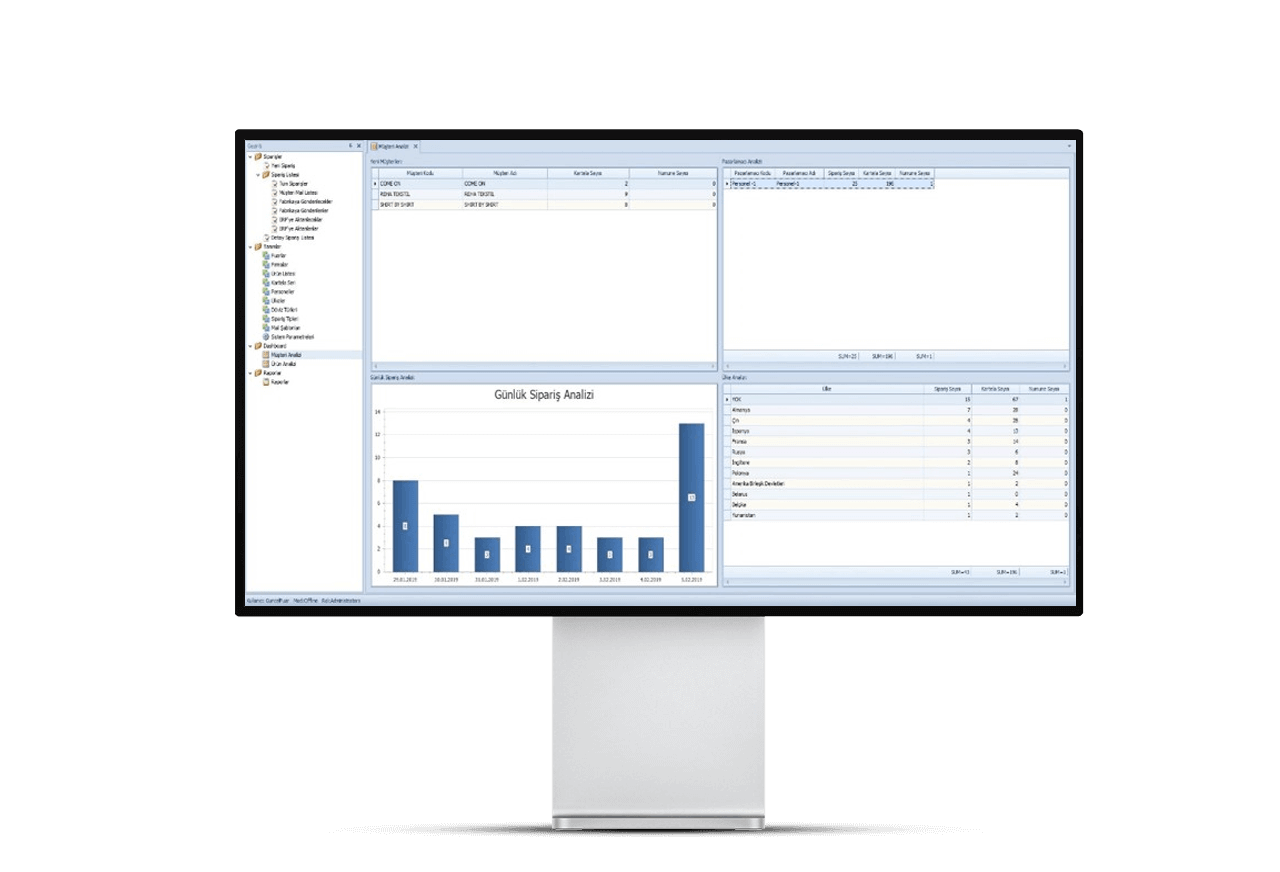

WHAT IS IT?

- You can instantly see your looms’ active status, your facility’s efficiency, and real-time information about stops and breaks. You can also filter by Product Code and machine-specific criteria.

- With the Gantt screen, you can analyze when the job assigned to the loom will finish and easily assess the subsequent tasks to be connected.

- You can generate real-time status reports of your business and report the instant status of all your looms as you desire.

- Through analysis reports, you can quickly obtain information about your business’s efficiency factors contributing to efficiency decline such as stops, breaks, idle waiting, etc. You can do this on a yearly, monthly, weekly, daily, and custom date range basis.

WHAT IS IT?

The Andon system enables employees and managers to monitor production in real time by tracking production issues and shift efficiencies as they occur.

- Critical Looms

For instances where looms experience stops such as weft change, warp change, master waiting, electrical faults, etc., and the predetermined optimal time is exceeded, the system can publish these incidents on the critical loom list.

- Real-Time Weft Issues

You can track weft issues in real-time and view the most problematic looms during shift transitions.

- Real-Time Warp Issues

You can monitor warp issues in real-time and display the most problematic looms during shift transitions.

- Top Performer Staff

Photos and performance values of staff achieving the best performance on active shifts, daily, weekly, or monthly, are displayed on screens. You can contribute to employee motivation through a reward system.

- Team – Shift Efficiency Analysis

Real-time shift analyses are published, allowing for comparison by displaying the latest efficiencies of other shifts.

- Live Monitoring

All these functions can be presented within the company using LCD-LED Android TV.